In today’s industries, cleanliness is not just about appearance—it directly affects performance, safety, and product life. From laboratories to manufacturing plants, Ultrasonic Cleaning has become a trusted solution for removing contaminants that traditional cleaning methods simply cannot reach. In this blog, I’ll explain how ultrasonic cleaners works, why it is so effective, and where it delivers the most value in real-world applications.

What Is Ultrasonic Cleaning?

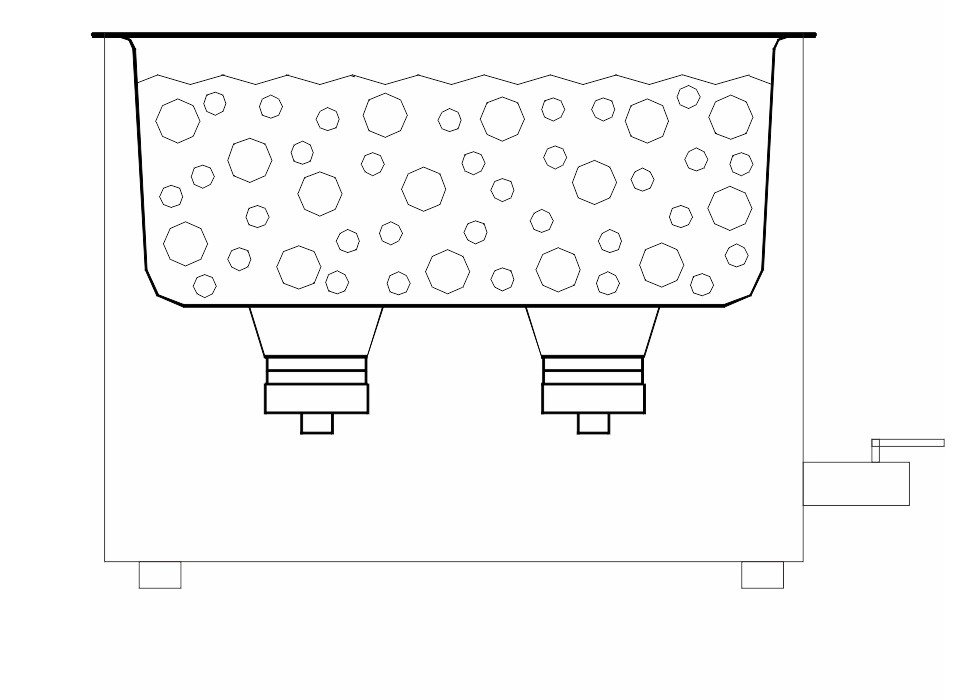

Ultrasonic Cleaning is a process that uses high-frequency sound waves, usually between 20–40 kHz, transmitted through a liquid cleaners solution. These sound waves create microscopic bubbles in the liquid through a phenomenon known as cavitation. When these bubbles collapse, they release energy that dislodges dirt, grease, oils, and microscopic contaminants from surfaces—even from tiny crevices and blind holes.

From my experience, this method is far superior to manual scrubbing, especially when dealing with complex or delicate components.

How Ultrasonic Cleaning Works

The working principle of ultrasonic cleaners is simple yet powerful:

- An ultrasonic generator produces high-frequency electrical signals

- Transducers convert these signals into sound vibrations

- Vibrations pass through the cleaning liquid

- Millions of microbubbles form and collapse

- Contaminants are removed without surface damage

What makes Ultrasonic cleaners stand out is its ability to clean evenly and consistently, regardless of the shape or complexity of the object.

Key Benefits of Ultrasonic Cleaning

From a practical point of view, ultrasonic cleaners offers multiple advantages across industries:

1. Deep and Uniform Cleaning

Ultrasonic waves reach areas that brushes, sprays, or wiping cannot access. This ensures complete cleaning even in internal passages.

2. Time and Labor Efficiency

Once the parameters are set, the system cleans automatically. This significantly reduces manual labor and cleaning time.

3. Safe for Delicate Parts

Unlike abrasive cleaning methods, Ultrasonic cleaners does not damage fragile components such as lenses, sensors, or precision instruments.

4. Eco-Friendly Process

It uses less chemical solution and water compared to conventional methods, making it an environmentally responsible option.

5. Consistent Results

Every cleaning cycle delivers repeatable results, which is essential in quality-controlled environments.

Applications of Ultrasonic Cleaning

Ultrasonic cleaning is widely used across different sectors due to its versatility:

- Laboratories: Cleaning glassware, pipettes, and instruments

- Medical & Dental: Sterilization of surgical tools and dental instruments

- Manufacturing: Removing grease, metal shavings, and polishing residues

- Electronics: Cleaning PCBs, connectors, and micro-components

In my view, any industry that values precision and reliability can benefit from ultrasonic cleaners systems.

Choosing the Right Ultrasonic Cleaning System

Selecting the right system depends on several factors:

- Size and material of items to be cleaned

- Type of contamination (oil, dust, biological residue)

- Required cleaning intensity and frequency

- Tank capacity and ultrasonic frequency

Using the correct cleaning solution and operating parameters is just as important as choosing the right machine.

Common Mistakes to Avoid

To get the best results from Ultrasonic cleaners, avoid these mistakes:

- Operating the system with insufficient liquid

- Using incorrect or overly aggressive chemicals

- Overloading the tank

- Running the machine for excessive durations

Proper usage not only improves cleaning efficiency but also extends machine life.

Conclusion

From my perspective, Ultrasonic cleaners is not just a modern alternative—it is a necessity for industries that demand precision, consistency, and efficiency. Its ability to remove contaminants at a microscopic level makes it unmatched by traditional cleaners methods. Investing in the right ultrasonic cleaning system is a smart move for any professional environment.

Contact Us

Website: www.galaxylab.in

Phone No.: +91-9910667175

FAQs on Ultrasonic Cleaning

Q1. Is ultrasonic cleaners safe for delicate items?

Ans. Yes, ultrasonic cleaning is gentle on delicate parts when used with the correct frequency and solution.

Q2. How long does an ultrasonic cleaning cycle take?

Ans. Typically, cycles range from 5 to 20 minutes depending on contamination and material type.

Q3. Can ultrasonic cleaning remove oil and grease?

Ans. Absolutely. It is highly effective in removing oils, grease, and industrial residues.

Q4. What liquid is used in ultrasonic cleaners?

Ans. Water-based solutions with specific detergents are commonly used for optimal results.

Q5. Is ultrasonic cleaners suitable for industrial use?

Ans. Yes, ultrasonic cleaning systems are widely used in industrial, medical, and laboratory environments.